NEW & IMPROVED DESIGN!

Now with 2X more TEETH

Protect your drive train and propeller with the best rope, line & debris cutter there is.

Discover the secret that commercial fishermen all know about preventing line and weed tangles on their props and shafts. The Shaft Shark has been installed successfully on hundreds of trawlers, ski boats, commercial working boats, power cruisers and sailboats. The U.S. Coast Guard installs serrated-edge weed and line cutters on their boat’s prop shafts so they will never be disabled with a fouled prop. A simple, serrated, circular blade that is made in two pieces that fit easily around any size prop shaft without removing the propeller, the stainless steel Shaft Shark can be installed in minutes and will save you thousands of dollars in repair bills. The Shaft Shark is simple, durable and effective.

AhoyCaptain is pleased to offer the Shaft Shark propeller protection device. It is the best line & weed cutter there is ... available for both power & sail. The Shaft Shark is a serrated edge circular blade … machined from high quality (316L) type stainless steel. It is available as a split two piece unit for quick and simple installation. Also available as a single piece unit for larger shafts.

What is a Shaft Shark?

The Shaft Shark is a serrated edge circular blade … machined from high quality (316L) type stainless steel. It is available as a split 2 x piece unit for quick and simple installation. Also available as a single piece unit for larger diameter shafts.

What does Shaft Shark do?

Attached to your shaft just forward of your propeller, it rotates with the shaft, cutting away any rope, weed or debris that might try to entangle your shaft & propeller while you are underway.

Why do I need a Shaft Shark? Why do I need a Shaft Shark?

• To keep your propeller free from rope, weeds and underwater debris.

• Eliminate the possibility of damage to your shaft, propeller and strut.

• Eliminate the need for being towed due to fouled stern gear or propeller.

Will the Shaft Shark affect my boats performance?

The SHAFT SHARK is sized to both the shaft diameter and the propeller hub diameter to ensure the lowest drag and minimal waterflow factors for the boat and propeller efficiency. Overall these two factors will vary depending upon the speed of the boat … the propeller hub diameter ... and the size of the SHAFT SHARK installed. This is why there are different model units to suit all shaft and hub combinations.

Will my Shaft Shark require any maintenance?

With no moving parts maintenance is minimal. There is nothing to maintain or replace on an annual basis. The edges can be re-sharpened when necessary.g.

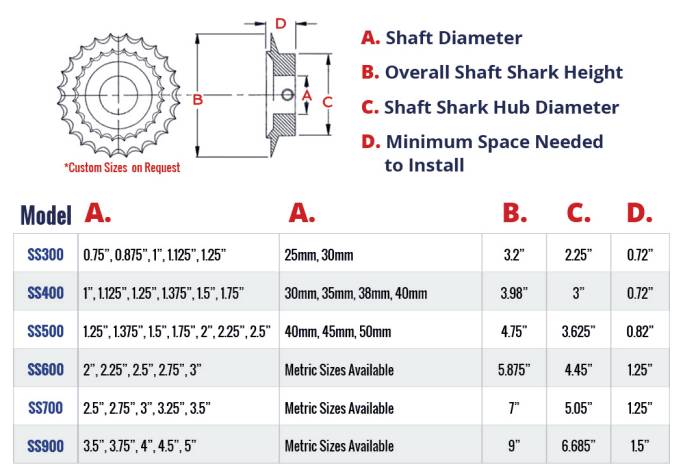

How do I choose the right Shaft Shark?

Pick a model that:

1. Has a range of shaft diameters that your propeller shaft diameter falls within.

2. Has a dimension “C” that is equal to or larger than the hub on your propeller strut.

|

How do I install my Shaft Shark

All Shaft Shark units are split units so installation is simple and quick. No need to remove the propeller to install. Installation underwater by a diver? … Yes, simple & easy.

Models SS300, SS400, SS500 require 0.90 inch (23mm) of shaft clearance between the cutlass bearing and the propeller hub. Models SS600 & above require 1.25~1.50 clearance. This allows for sufficient clearance with the cutlass bearing for shaft movement when maneuvering and for water-flow through the cutlass bearing when motoring.

|

|

Before installing, measure the distance from the forward edge of the propeller hub to the aft end of the cutlass bearing. This should be at least 0.95" (24mm). Note in the drawing that the Shaft Shark should be installed up against the propeller hub, not against the cutlass bearing and for thrust movement when motoring.

Split Model Installation

|

- Do not remove the propeller.

- Separate the two halves of the unit and install onto the shaft.

- Install the Shaft Shark with the AFT side facing aft.

- When tightening the screws, make sure the gaps are equal on both halves.

- It is always advisable to use loctite or something similar on the screws

|

|